Today I’m going to review one of the well-known PCB manufacturers in India, PCB Power.

PCB Power is a 20 years old Indian PCB manufacturing company located in Gujrat. They also provide PCB layout, component sourcing, assembly & stencil manufacturing services.

Over the years, I have used PCB Power services many times for various projects, but I couldn’t review them as the PCBs I worked on were for commercial projects. I have been working on a personal project which is an extension of my earlier project called Constant Current Dummy Load.

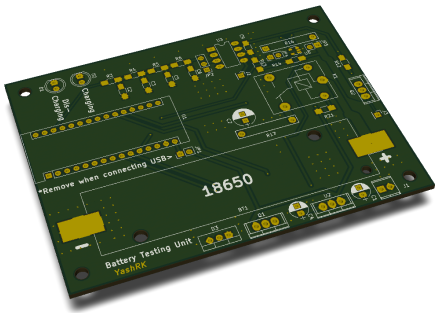

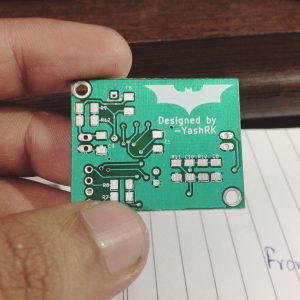

Below is the 3D rendering of the PCB in KiCAD with the board I got from PCB Power.

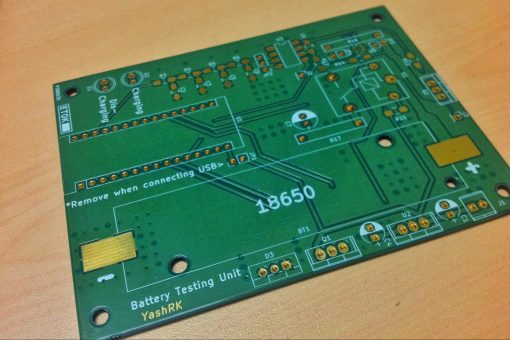

“Above image is not clear as my mobile didn’t take a good picture in indoor lighting, but the board came out very good!”

Given PCB Specifications:

- Dimensions: 100 mm x 75 mm

- Layers: 2

- Start Copper Thickness: 35 µm

- Finish Copper Thickness: 60 µm

- Surface Finish: Immersion Gold / ENIG

Following are a few parameters that I consider while deciding the quality of PCB:

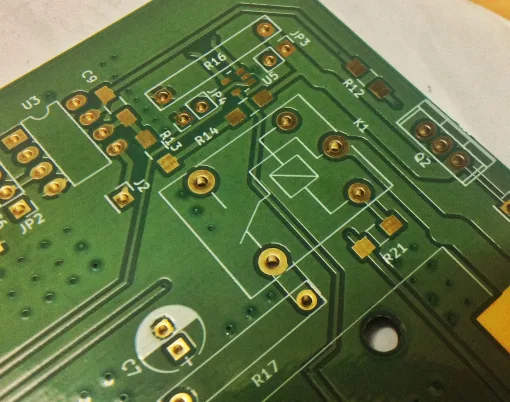

- Alignment:

- Solder mask alignment was perfect. I couldn’t see any misalignment from one side of the board to the other.

- The drill was also well aligned. The drills hole we spot-on in the center of the pad, and there were no breakouts.

- Via & Pads:

- Solder mask covered all the vias that I wasn’t expecting as I didn’t specifically mention that I needed it.

- Vias & Pads came out very good. There were no breakouts in vias.

- Plated through-holes also came out well and had a proper connection between layers.

Other Considerations:

- Dimensions:

- Dimensions of the PCB and the edge cuts were accurate.

- Board has been tab routed from all four sides. And there was a total of six mouse bite/tabs marks along the edge of the board.

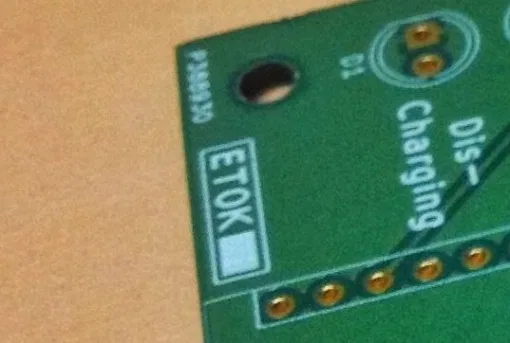

- Silk Screen:

- The silkscreen was very accurate, there was no bleeding, and the text resolution was precise enough that there weren’t any visible dots.

- Gerbers:

- It is important to me that the manufacturers do not touch my Gerbers. In the past, I had cases where one of the local PCB manufacturers removed vias from my board because he thought there were too many vias without notifying me in advance.

- PCB Power didn’t touch my Gerbers and, in the past, they have notified me if they find a fault in the PCB.

- Manufacturers marking:

- No one likes any manufacturer’s markings on their front silkscreen, especially if the board is in a case or being used as a front panel.

- PCB Power has added an ET OK mark with a tracking number on the front silkscreen. After a closer look, I found that they do provide an option to not print the ET OK on the silkscreen, but I guess they might still print the tracking number – unconfirmed.

- Service

- Cost: Costing I got from PCB power is quite competitive compared to other Indian & international (Chinese) manufacturers, considering the added shipping cost.

- Time to delivery: I ordered PCBs with a delivery term of 28 Days to get low cost, but luckily they were delivered to me within a week.

Conclusion:

I’m positively pleased with the quality of boards that I got from PCB Power. I would mention one con that I have found when working with them on a commercial project. They provide us various PCB-related services. Once, we used them as a turnkey solution to manufacture, procure parts, and assemble the PCB. They ended up providing us different quotes for each service. If you have multiple boards, as I did, you end up having 10 – 15 invoices, which you have to go through each of them to find irregularities, track them, and get them rectified from PCB Power which takes up a lot of time and is very annoying.

I am also looking forward to review other PCB manufacturers in India.

One new thing I tried on this board. That is to print my name on the board by removing the solder mask over a flood plain instead of traditional silkscreen printing. With the board having a golden surface finish, the text looked awesome.

Very well illustrated review. I might as well send my design to them. On a side note, I have had a great experience with JLC and Lion circuits too. Both of them do a decent job.

Thanks!

Cost wise JLC has no match but quality of PCB is better with PCB Power. But I have not used Lion Circuits’ services yet, I will try them next.